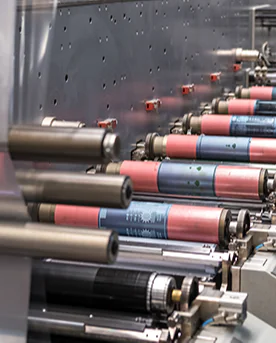

Features: Blend of Medium ACN NBR and PVC in ratio of 70:30. Medium viscosity grade.

End Uses: extruded and molded products suitable for outdoor applications in automotive and industrial applications.

NVC 70E provides Oil, fuel, thermal resistance as well as Ozone and environmental resistance. It has easy processibility, and better filler incorporation.

Our Business

Our Business

Disclosure under Regulation 46 of SEBI (LODR) Regulations

Disclosure under Regulation 46 of SEBI (LODR) Regulations